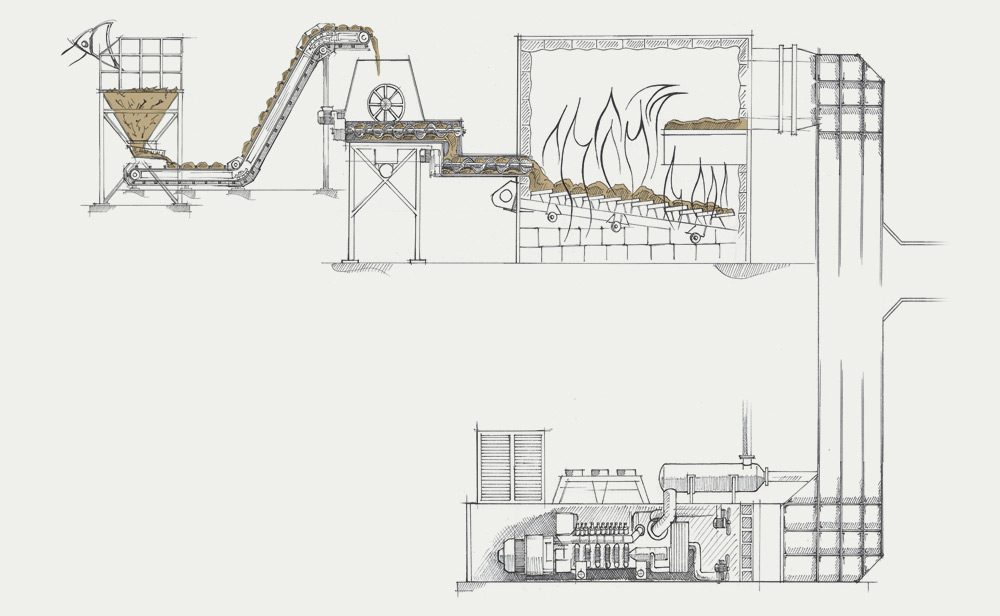

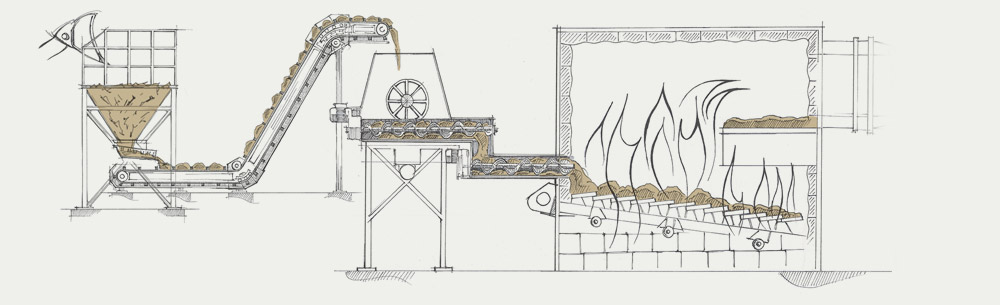

A wood boiler requires a continuous feeding system which not only takes into account the particularities of fuel,

but also ensures hermetic sealing during the introduction of fuel into the firebox.

We design and manufacture complete feeding systems for boilers from biomass storage to input into firebox.

The feeding chain consists essentially of a hopper, an extractor, conveyors (chain or belt),

a feeding buffer and a screw conveyor to introduce fuel into the firebox.

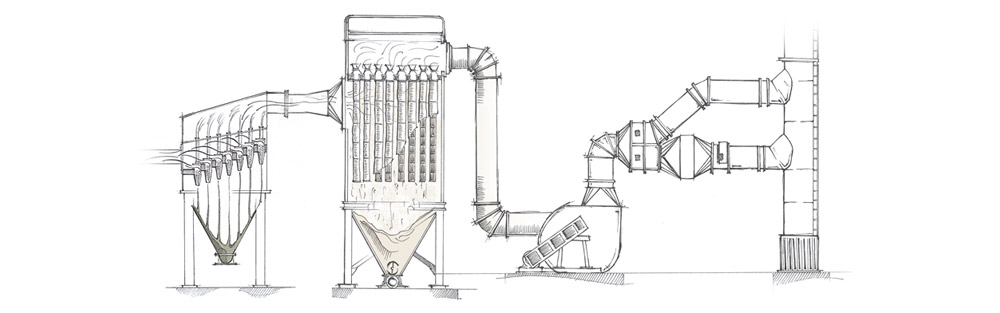

The ashes produced by biomass combustion must be evacuated continuously and for this purpose we design,

manufacture and install dry and wet ash evacuation systems.

We use chain conveyors to extinguish and evacuate ashes for wet ash handling systems,

and chain conveyors or screw conveyors for dry ash handling.

To avoid the entry of cold air into a hot smoke flow, and so to prevent the condensation of combustion water steam,

we install very effective rotary valves, of our design and manufacturing

on the ash discharge from multicyclones and from filters.

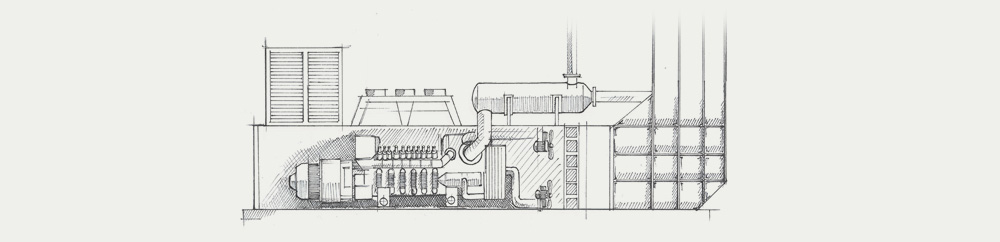

In order to optimize the use of energy and increase energy efficiency,

we design and install electric energy generation systems with hot air recovery.

This system called energy cogeneration is adopted

when both electricity and thermal energy are necessary in a factory at the same time.

Energy cogeneration is based on an internal combustion engine equipped with an alternator for electricity production,

and a thermal exchanger for heat recovery.

To be economically viable cogeneration must be simple and rapidly amortizable.

To this purpose, we suggest the installation of systems tailored to the factory’s electricity needs and not to heat consumption.

To increase the overall efficiency of cogeneration, when possible, we prefer to avoid complex thermal exchange systems

and to use heat, produced by the engine directly in the form of hot air or hot water.