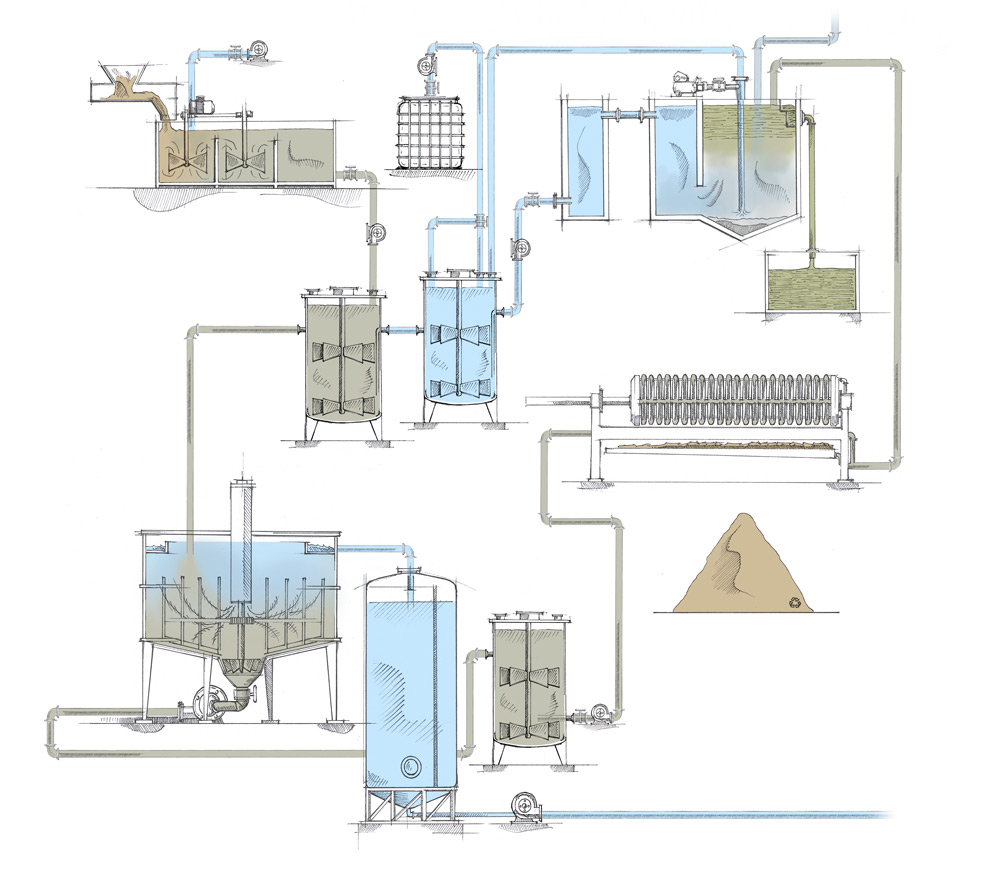

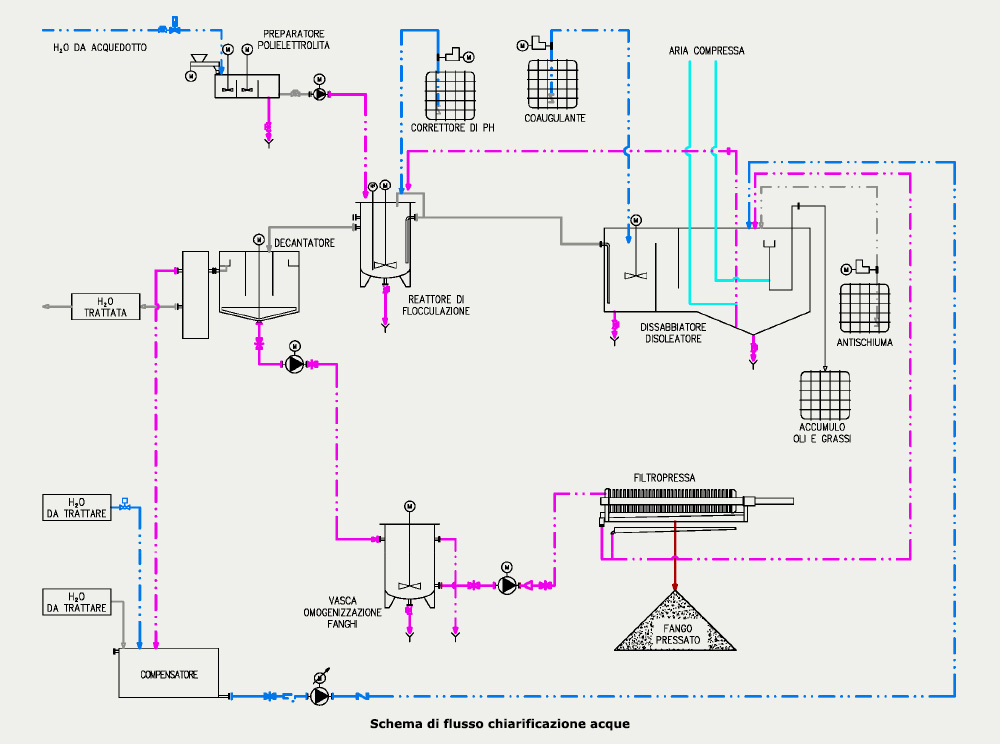

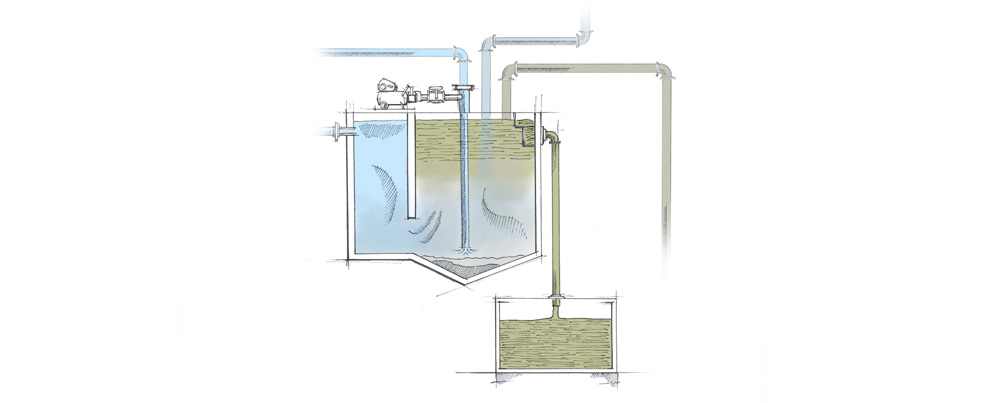

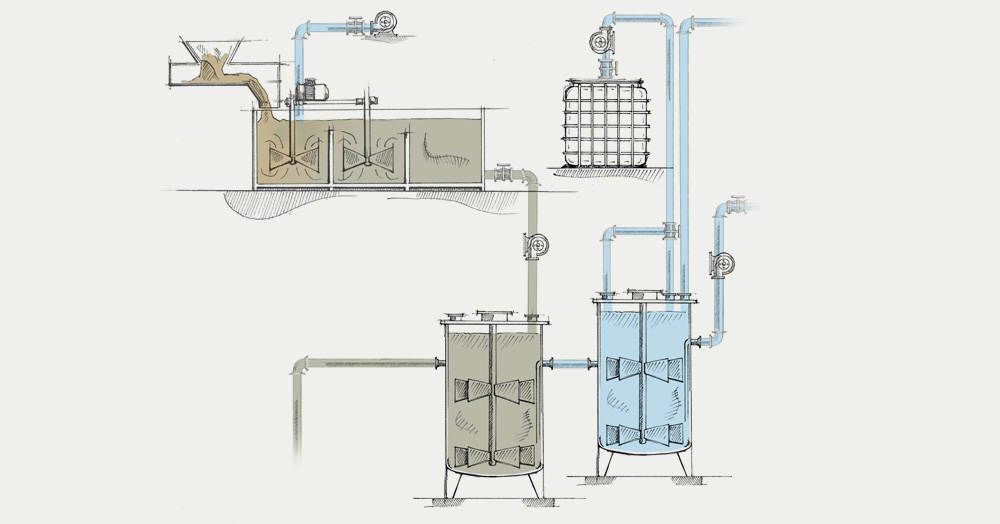

Polyelectrolyte and other additives, required for the formation of sludge flakes, are prepared in suitable equipment,

and then are added by means of metering pumps, to the continuous flow of wastewaters.

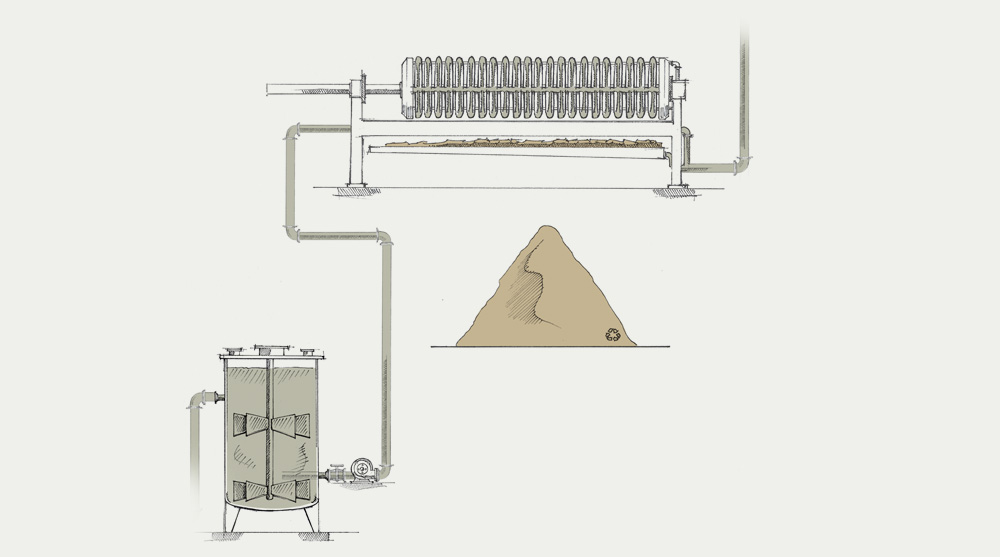

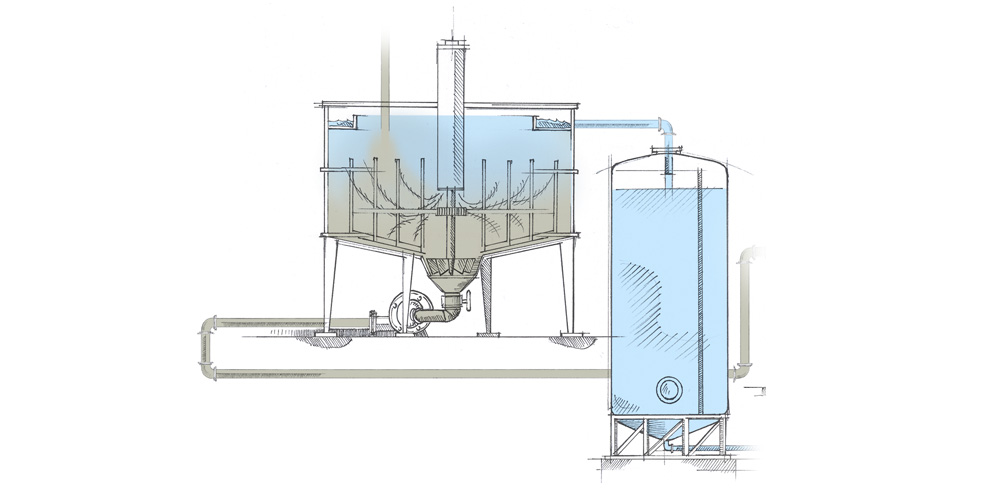

The thickened and homogenized sludge is sent to the filter press.

The choice of the filter press is made by taking into account the quantity of sludge produced by the clarification unit

and by the characteristics of mud, namely, the amount of organic matter, what sand or abrasive material it contains,

how adhesive it is to the filtration canvases etc.

Before choosing a dehydrating machine, we carry out some filtration stests,

usually together with the machine manufacturers, in order to assess the type of filtration canvas to be used and filtration time.

For some types of sludge it is possible to employ dehydration units of a centrifugal kind, instead of the filter press.