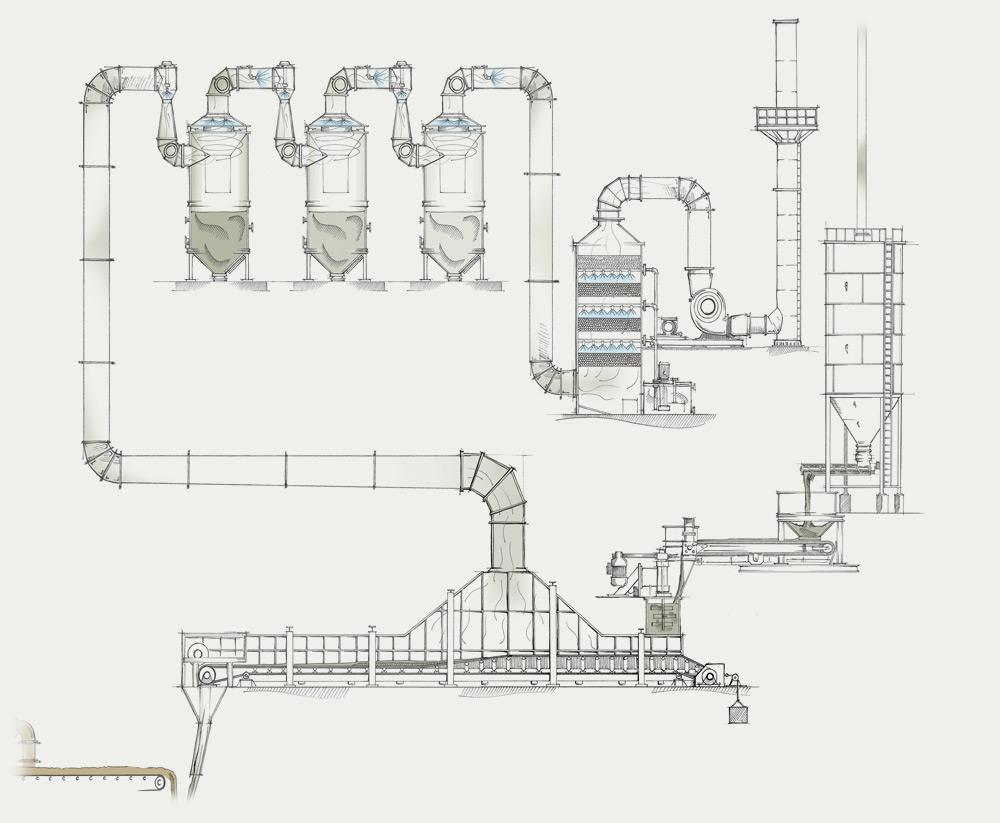

Kuhlmann den

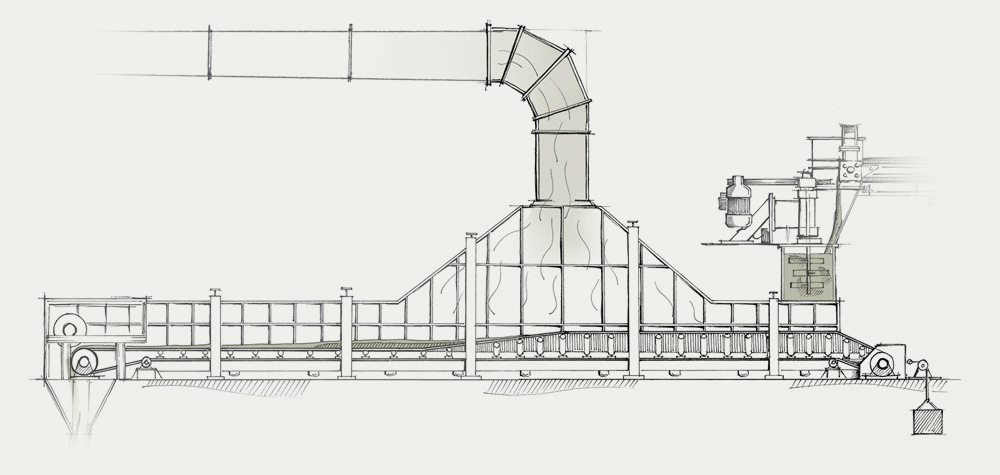

A conveyor belt, moving at a very low speed, completes the reaction between acid, water,

and the phosphate rocks in order to transform insoluble phosphate into soluble phosphoric anhydride (P

2O

5).

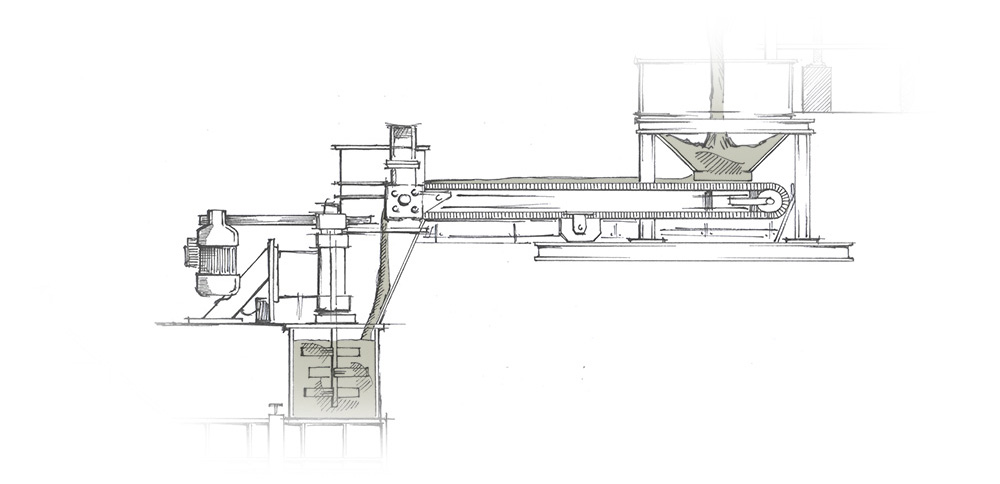

A drive unit, positioned in the discharge part of the

Kuhlmann Den, drives the conveyor belt,

and a counterweight, attached to the return drum, gives it tension.

The first part of the conveyor belt is shaped like a trough and the final part is flat.

The slurry coming from the dynamic mixer falls into the trough zone of the belt, while the gases and the steams,

that are produced from the chemical reactions, dry the slurry, which is thus transformed into a semi-solid mass.

After a few minutes the reactants and the reaction products assume a solid consistency, so that they can be transported by the flat belt.

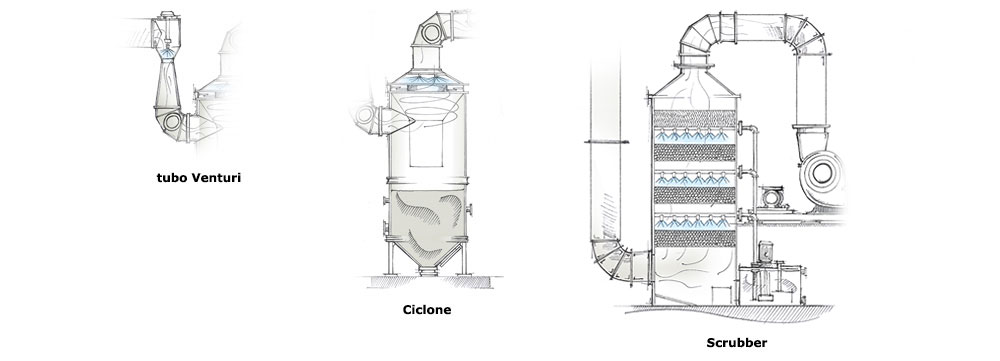

Above the entire length of the conveyor belt is a hood, which is made of an anti-acid material

and ensures the suction of gases and steams produced by the chemical reaction.

At the opposite end of the mixer, the drive pulley is placed in a large hood together with the lump crusher that breaks up the solid phosphate,

which is now at the end of the reaction.

The final product, that has the consistency of a slightly wet powder,

is convoyed to the warehouse where all the chemical reactions involved are completed.